Wuxi CMC machinery Co., Ltd. is located in wuxi, Jiangsu

province, near Shanghai, which is specializing in designing,

manufacturering, sales and service of light pole machines.

Our company has own unique technology and good customer base in the

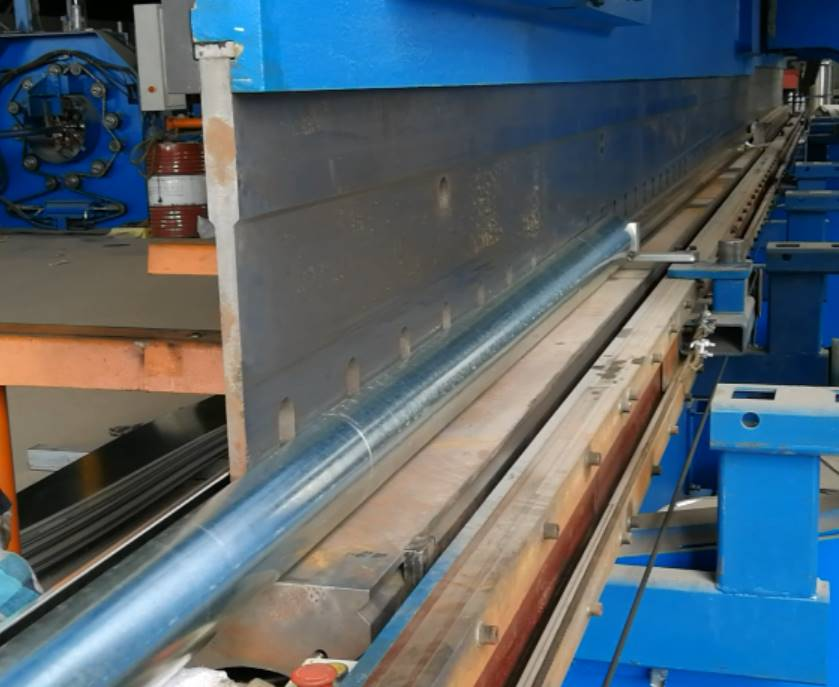

development and production of light pole machines complete line. Our main products include cut to length line, CNC tandem

hydraulic press brake, base plate welding machine, CNC light pole

door cutting machine, high mast assembly & straightening machine,

CNC portable flame cutting machine, gantry type welding machine for

high mast, steel plate slitting machine, light pole shut-welding

machine, hot dip galvanizing equipment and so on.

Our self-developed cut to length line, output from steel coil to

isosceles trapezoidal plate directly. It has high automation, fast

speed, and obtained the national new practical patent. Based on CNC

tandem hydraulic press brake, we have made many improvements,

making the machine especially suitable for the rapid and efficient

production of light poles. To meet customers’ demands, we developed

CNC light pole door cutting machine, base plate welding machine,

automatic double / four head drilling machine, high mast automatic

welding machine, etc.. we continuously optimize and improve

our products to meet the light pole industry. It greatly changes

the situation of manual work and improve the quality and efficiency

of light pole production.

More than 80% of our products are exported to overseas markets,

such as Thailand, Malaysia, India, the United States, Mexico, Brazil, Russia, Latvia, kazakhstan, Algeria, Egypt,

Ethiopia, the Middle East, etc.

Our engineers have rich experience in installation and

commissioning abroad, good skills in English communication, technical skill and remote service ability to solve problems.

After years of running, we have become a team with innovative

working habits, close cooperation with each other, holding the key

technology of light pole machines, growing up to a 100%

trustworthy team.

More than light pole machine produciton, we also set up a joint

venture named Jiangsu XinLingYu Intelligent Technology Co., Ltd. in

Xuzhou city, Jiangsu province in 2017 year. It fabricates hot dip galvanizing

line/equipments, can meet customers' requirements of anti-corrosion treatment for light pole and high mast pole.

Based on years of experience and knowledge of the original hot-dip

galvanizing, we continue to develop and innovate the HDG process.

It has reached a very advanced technical level. We have supplied

both light pole machines / lines and hot-dip galvanizing lines to

multiple customers.

At present, our company runs very stably, has good financial

condition and step in a strong growth period.

We hope to establish a good relationship with more customers,

develop and make progress synchronous.